Key Points:

- Hyundai Mobis has developed an AI system that uses sound analysis to assess product quality. The system is currently used at the Changwon plant.

- Acoustic AI can determine product quality in one second, improving the accuracy and speed of inspections.

- Hyundai Mobis plans to extend the use of Acoustic AI to other manufacturing lines, including brake equipment.

- The company aims to gather more data to refine the AI system further, ensuring continuous improvement in quality checks.

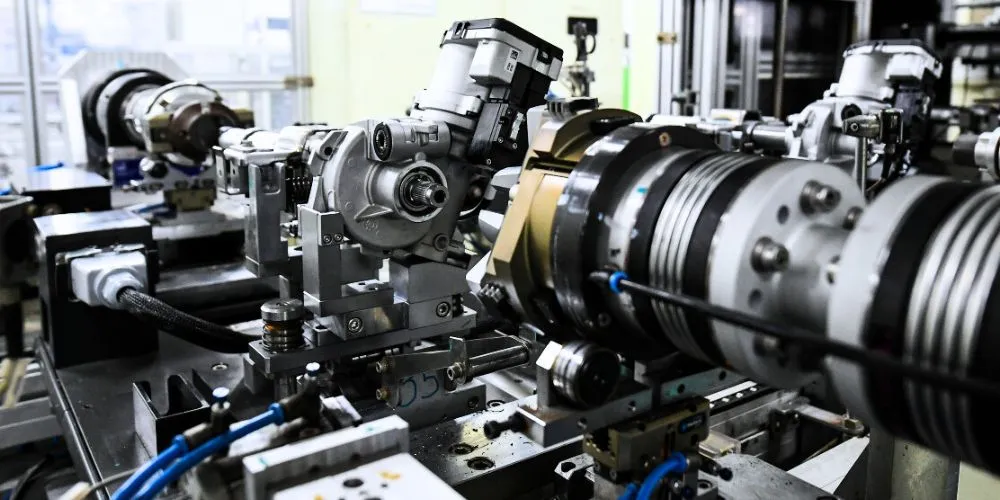

Hyundai Mobis, a subsidiary of Hyundai Motor Group, announced on Wednesday the development of a sound-based artificial intelligence system designed to enhance the accuracy of product quality checks by analyzing sounds generated during inspections. This advanced AI technology, dubbed Acoustic AI, has already been implemented at Hyundai Mobis’s Changwon plant in South Gyeongsang Province, which manufactures motor-driven power steering (MDPS) products.

Acoustic AI operates on an algorithm that interprets specific sounds to make quality assessments, distinguishing it from generative AI technologies based on language processing. The AI system can evaluate the quality of each product in just one second by analyzing the sound waves produced by the spinning motors in the MDPS units. This rapid assessment helps identify any irregularities in the products.

Before the advent of Acoustic AI, products that did not meet quality standards were flagged by an automated system and reassessed by human experts; this process was time-consuming and less efficient. Hyundai Mobis asserts that the new AI system significantly enhances quality checks’ speed and accuracy, streamlining the process.

Following its successful implementation at the Changwon plant, Hyundai Mobis plans to extend Acoustic AI to other manufacturing lines, particularly those involving brake equipment and other parts that generate noise during production. The company aims to continuously gather data to refine the AI system further and improve its accuracy.

“This initiative marks a pioneering example of process innovation not only in the automotive sector but also across the global manufacturing industry,” stated Choi Nak-hyun, vice president and head of digital transformation at Hyundai Mobis. “We will continue to introduce differentiated, new AI-based technologies for production, research and development, and improvements in the work environment.”

Hyundai Mobis’s commitment to integrating AI into its manufacturing processes highlights a broader trend within the industry toward automation and digital transformation. By leveraging AI to perform detailed and rapid quality checks, the company enhances its operational efficiency and ensures higher product quality standards.