Motor control is a fundamental aspect of automation and robotics, enabling precise movement and control of electromechanical systems across various industries. This comprehensive exploration examines the intricacies of motor control, elucidating its fundamental principles, key components, recent innovations, notable applications, and its transformative impact on manufacturing, transportation, and beyond.

Understanding Motor Control

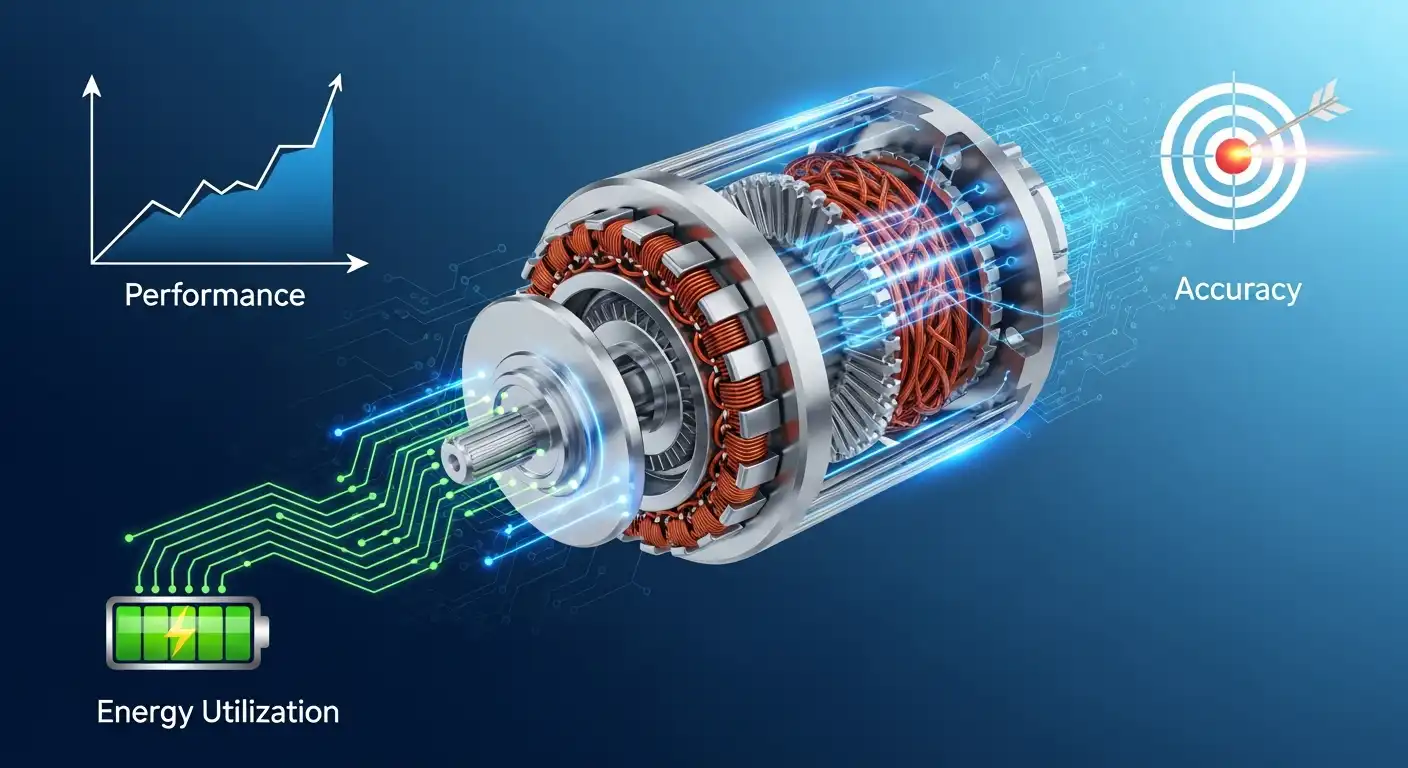

Motor control involves regulating and manipulating electrical signals to drive electric motors, ensuring accurate control of speed, torque, and position. It encompasses a range of techniques and technologies designed to optimize motor performance and efficiency in diverse applications.

Key Components of Motor Control

The core components of motor control contribute to its functionality and effectiveness in various applications:

- Motor Driver: An electronic device that controls an electric motor’s speed, direction, and torque by modulating the voltage and current supplied to the motor windings.

- Microcontroller or PLC: A programmable device that executes control algorithms, monitors feedback signals, and adjusts motor parameters to achieve desired performance objectives.

- Sensors: Devices that provide feedback on motor speed, position, and temperature, enabling closed-loop control and dynamic response to changing operating conditions.

Types of Motor Control

Motor control techniques can be categorized into two main types based on their control strategy and operation:

Open-Loop Motor Control

Open-loop motor control involves directly applying voltage or current to the motor without feedback control. It is suitable for simple applications without precise control, such as fan motors and basic conveyor systems.

Closed-Loop Motor Control

Closed-loop motor control utilizes sensor feedback to adjust motor parameters and maintain desired performance criteria. It offers superior accuracy, stability, and responsiveness, making it well-suited for applications requiring precise control of speed, position, and torque, such as robotics, CNC machines, and servo systems.

Recent Innovations in Motor Control

Recent innovations have advanced motor control technology, enabling higher performance, efficiency, and integration. Notable advancements include the adoption of brushless DC (BLDC) motors, the development of sensorless control algorithms, and the integration of predictive maintenance techniques.

Brushless DC (BLDC) Motors

BLDC motors offer improved efficiency, reliability, and performance compared to traditional brushed motors, thanks to their brushless design, electronic commutation, and higher power density. They are widely used in applications that require high-speed operation, precise control, and minimal maintenance.

Sensorless Control Algorithms

Sensorless control algorithms eliminate the need for position and speed sensors by leveraging motor model-based estimation techniques, back-electromotive force (EMF) detection, and advanced signal processing algorithms. They reduce system cost and complexity while improving reliability and robustness in motor control applications.

Notable Applications of Motor Control

Motor control technology has diverse applications across various industries and domains, powering various electromechanical systems and devices, from industrial robots and electric vehicles to household appliances and HVAC systems.

Industrial Automation

In industrial automation, it drives conveyor belts, pumps, compressors, and robotic arms, enabling precise movement, efficient production, and flexible manufacturing processes.

Automotive Systems

It regulates the operation of electric power steering, braking, and propulsion systems, thereby improving vehicle performance, safety, and energy efficiency in electric and hybrid vehicles.

Challenges in Motor Control

Despite significant advancements, its technology faces challenges that impact its performance, reliability, and scalability in demanding applications. Addressing these challenges is crucial to ensuring the continued evolution and adoption of motor control technology.

Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) from power electronics and switching devices can disrupt motor control signals, leading to performance degradation, noise, and reliability issues. Shielding, filtering, and layout optimization techniques mitigate EMI effects and ensure stable motor operation.

Thermal Management

Managing heat generated during motor operation is critical for maintaining performance and reliability. Excessive temperatures can lead to motor overheating, insulation degradation, and component failure. Efficient thermal design, cooling systems, and temperature monitoring are essential for preventing thermal issues in motor control applications.

Future Trends in Motor Control

The trajectory of motor control technology indicates exciting trends that will further redefine its capabilities and applications in the era of automation and electrification. These trends promise to enhance performance, efficiency, and intelligence, ushering in a new era of motor control innovation and integration.

Integrated Motor Control Solutions

Integrating motor control algorithms, power electronics, and sensor interfaces into compact, energy-efficient modules enables seamless deployment across diverse applications, reducing system complexity and time-to-market for motor control solutions.

AI-Driven Motor Control

Integrating artificial intelligence (AI) algorithms, such as machine learning and neural networks, into motor control systems enables adaptive control, predictive maintenance, and fault detection, thereby improving the performance, reliability, and energy efficiency of motor-driven systems.

Conclusion

Motor control is a foundational technology in automation and electromechanical systems, enabling precise movement, efficient operation, and intelligent control across various industries and applications. From industrial robots and electric vehicles to household appliances and HVAC systems, the impact of motor control extends across a wide range of applications, reshaping how we design, manufacture, and interact with electromechanical systems in the digital age. Despite challenges, ongoing innovations in brushless motors, sensorless control algorithms, and integrated motor control solutions promise a future where motor control continues to push the boundaries of what is possible, unlocking new opportunities for efficiency, reliability, and automation in the modern world.