Researchers have delved into a comprehensive investigation to enhance the efficiency of commercial fluidized bed combustion (FBC) plants handling industrial waste sludge. Waste sludge, characterized by high moisture, volatile and toxic compounds, and ashes, poses operational challenges and necessitates meticulous attention for cost-effective combustion.

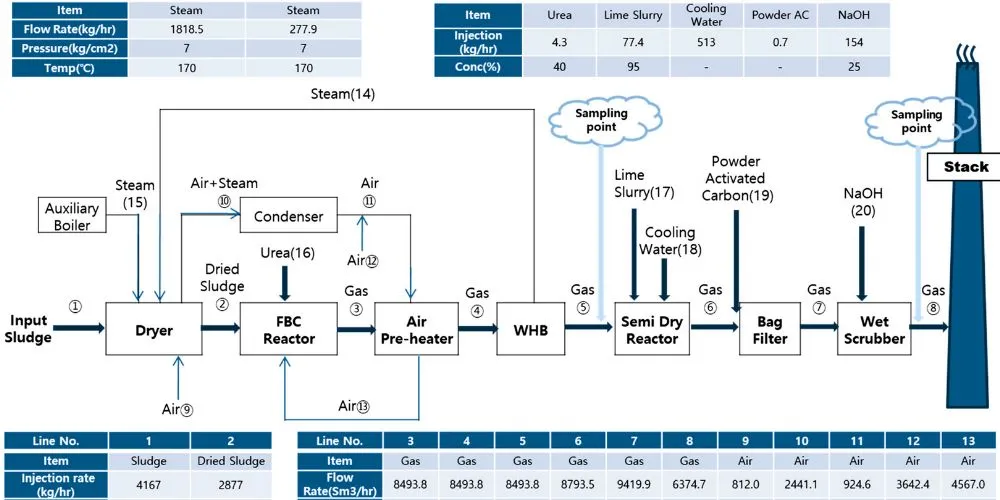

The research focused on a chosen commercial FBC plant, evaluating the mass balance of the FBC process and the performance of the air pollution control device (APCD). Researchers analyzed the fuel composition by calculating an incineration air flow rate of 4567 Nm3/h, increasing to 8493.8 Nm3/h after FBC combustion. Heat balance analysis revealed heat loss during combustion, with the incineration gas temperature dropping to 200 °C at the APCD inlet.

Hazardous air pollutant emission testing pinpointed optimal operation factors for lime slurry and NaOH injections in the semi-dry reactor and wet scrubber. Waste generation in the semi-dry reactor and wet scrubber was optimized at these factors, contributing to a more sustainable approach.

The study emphasized the critical role of monitoring the heat and mass balance of the FBC combustion process, especially due to the elevated moisture and toxic compound levels in waste sludge. Post-drying, the input sewage sludge decreased, leading to increased flue gas rates and decreased temperatures after combustion.

Given the organic compounds and chloride in waste sludge, the study highlighted the need to treat gaseous pollutants like NOx, SOx, and HCl carefully. While the control efficiency for SOx and HCl was 99% following additive injection, an alternative process was suggested for NOx control. The researchers found that APCDs efficiently captured coarse and fine particulates with 100% control efficiency. However, toxic metals enriched in fine PM at the outlet were not entirely captured by the APCDs.

After examining mercury compounds, the research found oxidized mercury dominated at the APCD inlet, transforming into particulate mercury after passing through the APCDs. This transformation was observed to be influenced by reactive additives in the Semi-Dry Absorber (SDA).

For economical and efficient APCD operation, factors and waste generation were determined based on Hazardous Air Pollutant (HAP) test results, leading to a substantial reduction in injection and potential waste generation compared to predicted design rates.

This research contributes valuable insights for the sustainable and cost-effective operation of FBC plants handling industrial waste sludge, emphasizing the importance of optimizing APCD operation factors and waste generation.