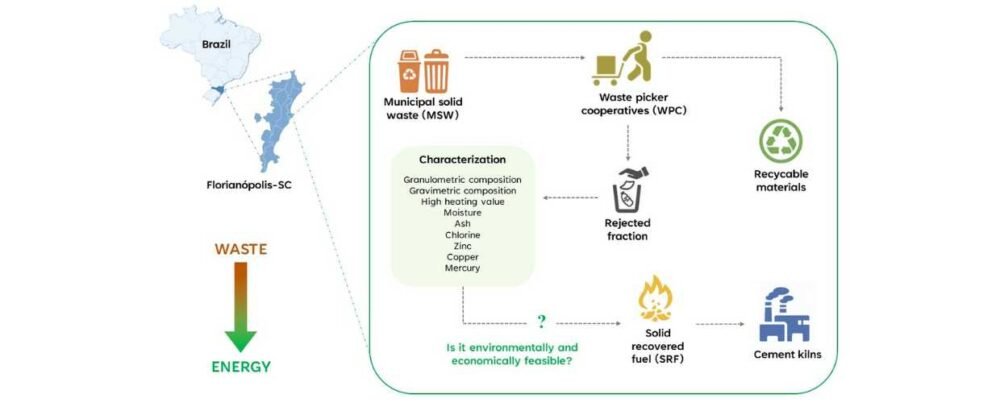

Two researchers, Valeria D’Ambrosio and Carlo Pastore, from Istituto di Ricerca Sulle Acque (IRSA) and the University of Bari Aldo Moro, have presented a case study in Brazil for evaluating Waste-to-Energy Potential to generate Solid Recovered Fuel (SRF) from Waste Picker Cooperative Rejects.

Investigating SRF Generation

In this research, the researchers have explored a sustainable waste-to-energy solution by examining the feasibility of producing solid recovered fuel (SRF) from discarded waste retrieved from waste picker cooperatives (WPC). Three distinct scenarios were constructed, varying the SRF and petroleum coke proportions utilized in cement kilns. The primary goal was to assess the viability of using this waste stream for energy generation and its potential for substituting conventional fuel sources in industrial processes.

Characterization, Emission Reduction, and Cost Analysis

The groundwork for this assessment involved obtaining samples of rejected waste from WPC in Florianópolis, Brazil. A comprehensive analysis determined these materials’ physical and chemical attributes. The study went further by quantifying the environmental benefits realized through integrating SRF into cement kilns, replacing traditional petroleum coke. This substitution resulted in notable reductions in atmospheric emissions, quantified for different scenarios. Furthermore, the financial aspects were investigated, and the costs associated with implementing an SRF facility were estimated, providing critical insights into the economic viability of this waste-to-energy approach.

Transforming Waste-to-Energy Resources

The findings revealed a promising waste-to-energy prospect. A substantial portion of the waste collected from WPC, approximately 60.29%, was found suitable for energy recovery; among the materials with potential for SRF production, plastic packaging, and paper constituted a significant portion, accounting for 75.26%. Notably, integrating SRF into cement kilns exhibited notable benefits for atmospheric emissions reduction. In three distinct scenarios, replacing petroleum coke with SRF led to reductions of 4.83%, 14.73%, and 13.37% in atmospheric emissions. Moreover, the economic evaluation highlighted the cost-effectiveness of SRF production. The analysis revealed that producing one ton of SRF cost around USD 6.00, which marked a remarkable decrease of 35 times compared to the costs associated with petroleum coke. These findings underscore the potential of harnessing rejected waste from WPC as a valuable and environmentally friendly alternative for waste-to-energy conversion.

The research showcases the potential of repurposing waste materials from waste picker cooperatives into a valuable energy resource. Producing solid recovered fuel (SRF) and integrating it into industrial processes can achieve environmental and economic benefits. This research underscores the significance of innovative waste management approaches in fostering sustainable energy solutions and addressing environmental concerns.