Key Points

- Beyond 3D printing, 4D printing adds the dimension of time, enabling printed objects to transform and respond dynamically to external stimuli.

- Enables adaptive biomedical implants that can adjust and evolve in the body, such as stents that adapt to blood vessel conditions.

- 4D printing supports structures that respond to environmental changes, enhancing energy efficiency and structural integrity over time.

- Promises innovations in fashion, electronics, and related domains, offering products that adapt to user needs and environmental changes.

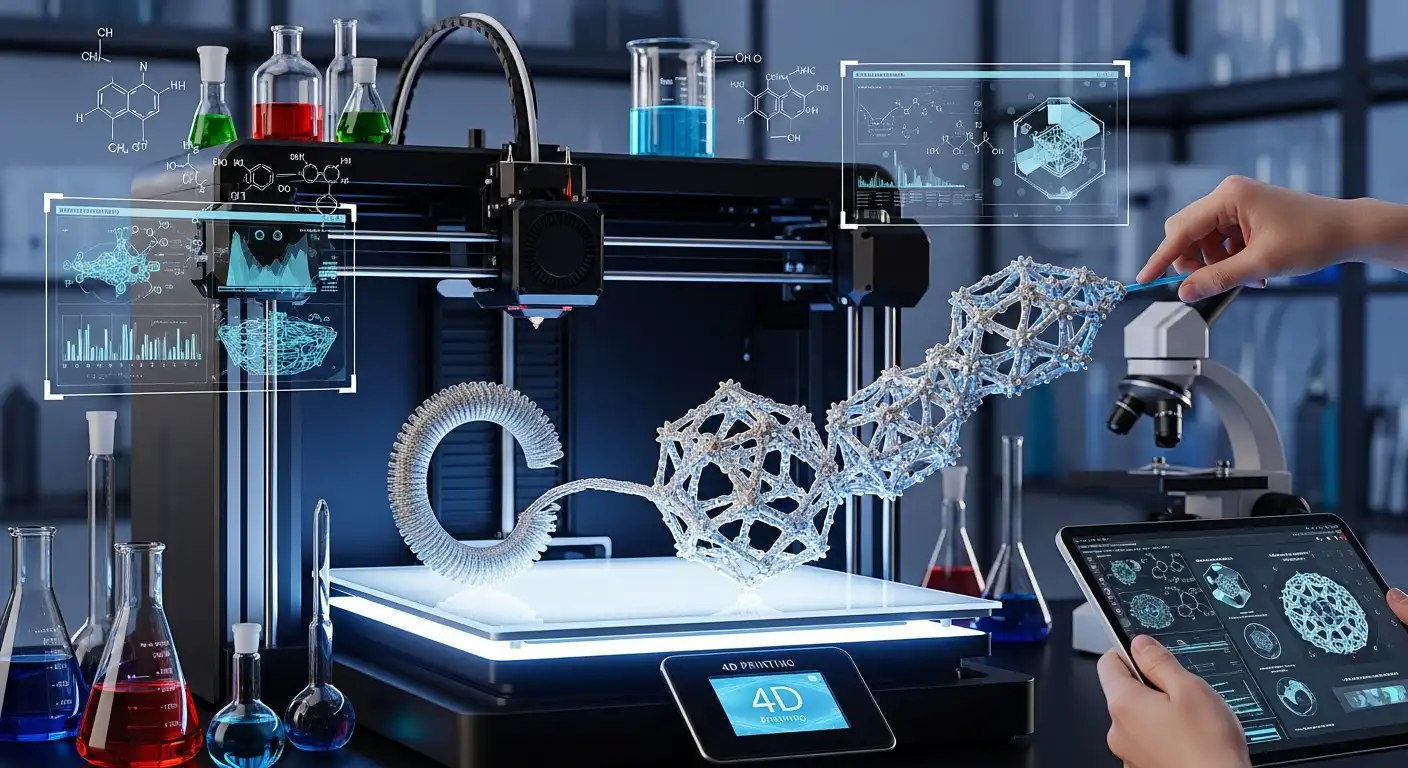

In a significant advance, the world is witnessing the emergence of 4D printing, a cutting-edge technology poised to revolutionize traditional manufacturing processes. 4D printing represents an evolution beyond its 3D counterpart, adding an unprecedented dimension—time. This innovative approach introduces dynamic and adaptive elements to printed objects, allowing them to transform, self-assemble, or respond to environmental stimuli over time.

Unlike conventional 3D printing, which creates static objects layer by layer, 4D printing introduces a fourth dimension by incorporating smart materials with intrinsic properties that enable shape-shifting or self-assembly. These smart materials respond to external triggers, such as heat, light, or moisture, activating predetermined changes in the printed structure. This transformative capability opens up a realm of possibilities across various industries.

One of the primary applications of 4D printing is in medicine. Researchers are exploring the creation of biomedical implants that can adapt and evolve within the human body over time. Imagine a stent that dynamically adjusts its shape in response to changing blood vessel conditions, or a smart orthopedic implant that optimizes its structure for enhanced healing as the patient recovers.

In architecture and construction, 4D printing holds promise for creating structures that can adapt to environmental conditions. Buildings with components that respond to temperature, seismic activity, or other factors could optimize their structural integrity and energy efficiency over time. Additionally, the technology enables the fabrication of self-assembling furniture or modular structures that can be transported efficiently before transforming into their final forms on-site.

The aerospace industry is also exploring the potential of 4D printing to create adaptive components for aircraft. Wings or surfaces that can dynamically adjust their shape in response to varying aerodynamic conditions could enhance fuel efficiency and overall performance.

As 4D printing advances, its impact on consumer products, fashion, and electronics becomes increasingly apparent. From self-adjusting eyewear to garments that adapt to temperature changes, the technology offers a spectrum of possibilities for customization and enhanced user experiences.

While 4D printing is still in its early stages, researchers and innovators are actively pushing the boundaries of what is achievable. As technology matures, it has the potential to redefine the way we manufacture, interact with products, and solve complex challenges across diverse industries, ushering in a new era of dynamic and responsive creations.