The electric vehicle (EV) revolution is no longer a distant promise; it is a present-day reality unfolding on our highways and in our driveways. For years, the narrative has been one of gradual progress, a steady march toward a future in which electric mobility is the norm. But as we accelerate towards 2025, we are not just on a steady march; we are on the cusp of a quantum leap. This leap is not being driven by sleeker car designs or more sophisticated infotainment systems. It is being powered by a revolution happening at the molecular level, deep within the humming heart of every EV: the battery. The battery is the single most important, most expensive, and most performance-defining component of an electric vehicle, and the advancements poised to enter the mainstream by 2025 will fundamentally reshape expectations for electric cars, shattering the final barriers to their mass adoption.

For too long, the conversation around EVs has been dominated by compromises—range anxiety, long charging times, and prohibitive costs. These were the ghosts in the machine, the persistent doubts that held back millions of potential buyers. The year 2025 will be remembered as the moment these ghosts were finally exorcised, not by a single silver-bullet solution, but by a powerful confluence of breakthroughs in battery chemistry, pack engineering, and intelligent management systems. We are moving beyond the era of simply improving lithium-ion batteries to one of making them smarter, safer, cheaper, and more diverse, while simultaneously preparing the ground for a post-lithium-ion world. This is not just an upgrade; it is a re-architecture of the very foundation of electric mobility.

The Unbreakable Trinity: Why the Battery Dictates the EV’s Fate

To understand the magnitude of the changes coming in 2025, we must first appreciate the central, almost tyrannical, role the battery plays in an EV’s design and user experience. Every decision an automaker makes, from a car’s price to its performance and physical shape, is dictated by the capabilities and limitations of its battery pack.

The success of any EV hinges on a delicate balance of three critical, often conflicting, factors, which we can call the “unbreakable trinity” of EV adoption.

Energy Density: The Cure for Range Anxiety

Energy density, measured in watt-hours per kilogram (Wh/kg) or watt-hours per liter (Wh/L), is the single most important metric for an EV battery. It specifies the amount of energy that can be stored per unit mass or per unit volume. Higher energy density enables a longer driving range from the same-sized battery pack, or a lighter, more efficient car with the same range. For a decade, the slow, incremental increase in energy density has been the primary weapon against “range anxiety”—the persistent fear that a driver will be left stranded with a dead battery. By 2025, new chemistries and cell designs will significantly enhance this metric, pushing the average EV range well beyond the 300-mile (480 km) psychological barrier and enabling 500-mile (800 km) ranges for premium models.

Charging Speed: The End of the Long Wait

If range anxiety was the first great hurdle, charging time is the second. While a gasoline car can be refueled in five minutes, early EVs took hours to recharge. The speed at which a battery can safely accept a charge is determined by its chemistry, thermal management, and the charging station’s power. The goal is to make the EV charging experience comparable to a stop at a gas station—a quick 10-15 minute break on a long journey that adds hundreds of miles of range. The battery technologies of 2025, particularly in anode materials and thermal management, are specifically designed to absorb power at blistering rates, making ultra-fast charging of 350+ kW the new standard.

Cost: The Path to Price Parity

The battery pack is the most expensive component in an EV, often accounting for 30-40% of the vehicle’s total cost. The industry’s holy grail has long been to achieve a battery pack cost at which the upfront cost of an EV is expected to reach parity with that of its internal combustion engine (ICE) equivalent, without relying on government subsidies. Thanks to manufacturing innovations and the adoption of lower-cost chemistries for certain market segments, the industry is poised to cross this critical threshold by 2025, unlocking a new wave of affordable, mass-market EVs.

Beyond this trinity, two other factors are crucial: longevity (the battery’s ability to operate for hundreds of thousands of miles) and safety (the elimination of the risk of thermal runaway and fires). The technologies of 2025 will deliver significant gains across all five of these fronts, creating a new generation of EVs that are not just viable alternatives but superior choices in every respect.

The Chemical Revolution: A Look Inside the Batteries of 2025

The most profound changes are happening at the level of battery chemistry. While the lithium-ion battery will remain the dominant technology in 2025, it will be a far more diverse and highly evolved family of chemistries than we see today. Automakers will no longer use a one-size-fits-all approach; instead, they will deploy a portfolio of battery types, each tailored to a specific market segment.

This chemical diversification is key to achieving an optimal balance of performance, cost, and longevity across vehicle types, from budget-friendly city cars to high-performance luxury sedans.

The Evolution of the Incumbent: High-Performance Lithium-Ion

The workhorse of the EV industry, the lithium-ion battery with a graphite anode and a nickel-manganese-cobalt (NMC) or nickel-cobalt-aluminum (NCA) cathode, is not going away. Instead, it is being pushed to its chemical limits to power the long-range and performance segments of the market.

By 2025, these premium lithium-ion cells will feature several key innovations that boost their energy density and charging speed.

- High-Nickel, Low-Cobalt Cathodes: Cobalt is the most expensive and ethically problematic material in an EV battery. The industry has been on a relentless quest to reduce its resource use. By 2025, the standard for high-performance cells will be NCM 811 (8 parts nickel, 1 part manganese, 1 part cobalt) and even more advanced NCM 9.5.5 chemistries. The higher nickel content directly increases the cell’s energy density, while the reduction in cobalt lowers its cost and improves its ethical footprint.

- The Silicon Anode Breakthrough: This is arguably the most significant chemical innovation to enter the mainstream in 2025. For decades, the anode (the negative electrode) in lithium-ion batteries has been made of graphite. Silicon is the heir apparent because it can theoretically hold over ten times more lithium ions than graphite, promising a massive boost in energy density (20-40%). The historical challenge has been that silicon expands and contracts during charging and discharging, which can lead to battery failure. By 2025, companies such as Sila Nanotechnologies and Group14 Technologies are expected to have solved this problem with engineered silicon materials that can be readily integrated into existing battery manufacturing lines. We will see the first EVs from automakers such as Mercedes-Benz featuring silicon-anode batteries that offer a significant increase in range for the same pack size.

The Resurgence of LFP: The Cost and Longevity Champion

Lithium Iron Phosphate (LFP) is not a new chemistry; it has been around for years, but was previously sidelined in the Western EV market due to its lower energy density compared to NMC/NCA. However, its powerful advantages in cost, safety, and longevity have triggered a massive resurgence.

By 2025, LFP will be the dominant chemistry for standard-range and entry-level EVs, playing a critical role in bringing affordable electric mobility to the masses.

- Cobalt-Free and Low-Cost: LFP cathodes utilize iron and phosphate, which are far more abundant and less expensive than the nickel and cobalt used in NMC/NCA batteries. This makes LFP cells significantly less expensive to produce, directly translating to more affordable EVs.

- Superior Longevity: LFP batteries can endure far more charge-discharge cycles than their high-nickel counterparts. An LFP pack can last for well over 3,000 cycles (potentially exceeding a million miles of driving) with minimal degradation, making it ideal for high-utilization vehicles such as taxis, delivery vans, and future robotaxis.

- Enhanced Safety: The chemistry of LFP is more thermally stable, making it far less prone to thermal runaway and fire, even if punctured or damaged. This inherent safety is a major selling point.

- Overcoming the Density Gap: While LFP’s cell-level energy density is lower, innovators such as BYD, with its “Blade Battery,” and CATL, with its cell-to-pack designs, have largely mitigated this disadvantage at the pack level by engineering a much more space-efficient pack architecture.

The Solid-State Tipping Point: From Lab to Limited Production

Solid-state batteries are the long-awaited “holy grail” of the EV industry. They replace the flammable liquid electrolyte found in conventional lithium-ion batteries with a solid, stable material (like a ceramic or polymer). For years, they have been a promising laboratory technology, but 2025 will mark their first tentative steps into the real world.

While solid-state batteries will not be in every mainstream EV by 2025, we will see them powering limited-run, high-end flagship vehicles from pioneering automakers, serving as a powerful proof of concept for the future.

- The Promise of Ultimate Safety: By eliminating the flammable liquid electrolyte, solid-state batteries are expected to be virtually immune to fire risk, representing a transformative improvement in EV safety.

- Massive Energy-Density Potential: Solid-state designs enable the use of pure lithium metal as the anode, the ultimate lightweight, high-capacity anode material. This could eventually lead to batteries with twice the energy density of today’s lithium-ion batteries, enabling a 500-mile car with a battery pack half the size and weight of current packs.

- Blazing-Fast Charging: The solid electrolyte is designed to be highly conductive to lithium ions, potentially enabling charging speeds that can replenish 80% of a battery’s range in as little as 10 minutes.

- The 2025 Reality: The primary challenge for solid-state has been manufacturing at scale and at a competitive cost. Companies like QuantumScape, Solid Power, and Toyota have made significant progress. By 2025, we will see the first automotive-grade solid-state cells being produced on pre-production lines. Automakers such as BMW and Mercedes-Benz, which have invested heavily in this technology, are expected to be the first to introduce vehicles featuring these next-generation cells.

The Dark Horse: Sodium-Ion Batteries for Ultimate Affordability

While lithium is the star of the show, its rising cost and geopolitical supply chain have created a huge incentive to find alternatives. Enter the sodium-ion battery. Sodium is one of the most abundant and cheapest elements on Earth, and it behaves chemically very similarly to lithium.

By 2025, sodium-ion batteries, led by giants like CATL, will begin to appear in the most affordable, entry-level city cars, particularly in the Chinese market, with a view to global expansion.

- The Cost Advantage: Sodium-ion batteries eliminate the need for lithium, nickel, and cobalt, making them dramatically cheaper to produce. This could enable the creation of a true sub-$20,000 EV.

- Performance Profile: The trade-off is lower energy density than that of even LFP. This means sodium-ion is not suitable for long-range vehicles. However, for a small city car with a range of 150-200 miles (240-320 km), it is a perfect fit. It also boasts excellent fast-charging capabilities and superb performance in cold weather, a traditional weakness of lithium-ion batteries.

- Supply Chain Security: By using common materials such as sodium, iron, and manganese, sodium-ion technology enables countries to establish a secure battery supply chain that is independent of the volatile global lithium market.

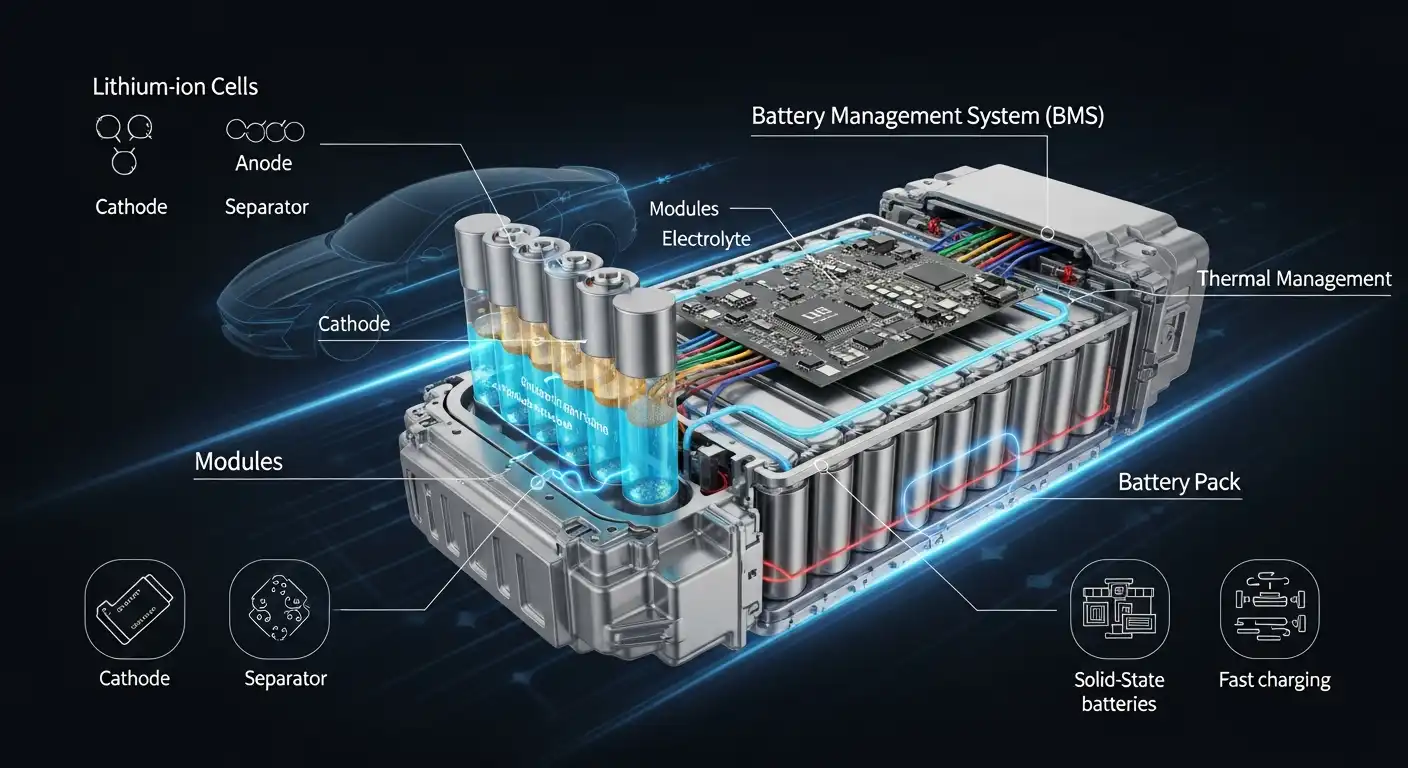

Beyond Chemistry: The Engineering Revolution in Battery Pack Architecture

The innovations of 2025 are not limited to the molecular level. A parallel revolution is occurring in how individual battery cells are packaged and integrated into the vehicle. The traditional method of bundling cells into modules, and then modules into a large pack, is being rendered obsolete by new, highly efficient structural designs.

These architectural breakthroughs are as important as chemical changes, as they enable automakers to increase range, reduce weight, and lower costs across any given cell chemistry.

From Modules to Integrated Packs: Cell-to-Pack (CTP) Technology

The traditional battery pack is full of wasted space—housings for modules, connectors, and other structural overhead. Cell-to-Pack (CTP) technology, pioneered by CATL and BYD, eliminates the module level. Individual prismatic or pouch cells are placed directly into the battery pack.

This seemingly simple change has a profound impact on the pack’s overall performance.

- Improved Volumetric Density: By removing modules, CTP designs can accommodate significantly more active battery material within the same volume. This boosts the pack’s overall energy density, allowing an LFP pack, for example, to achieve the same range as a traditional NMC pack.

- Reduced Cost and Complexity: Eliminating modules reduces the number of parts, simplifies the manufacturing process, and lowers the overall cost of the battery pack.

The Ultimate Integration: Cell-to-Chassis (CTC) and Structural Packs

Cell-to-Chassis (CTC) technology extends the CTP concept. It integrates the battery cells directly into the car’s body structure, thereby making the battery pack a load-bearing component of the chassis.

This holistic approach, exemplified by Tesla’s 4680 structural battery pack, fundamentally changes how cars are designed and built.

- Massive Weight Reduction: By integrating the battery casing into the car’s structure, CTC eliminates redundant structural components, thereby reducing the vehicle’s overall weight. A lighter car is more efficient, has better handling, and performs better.

- Increased Torsional Rigidity: A structural battery pack dramatically increases the stiffness of the car’s chassis. This results in improved vehicle dynamics, enhanced handling, and increased safety in the event of a crash.

- Simplified Manufacturing: The CTC approach enables automakers to construct cars in larger, more integrated sub-assemblies, thereby simplifying the final assembly line and reducing manufacturing costs. By 2025, this will become the benchmark for next-generation dedicated EV platforms.

The Brains of the Battery: AI-Powered Battery Management Systems (BMS)

The Battery Management System (BMS) is the sophisticated electronic brain that monitors and controls every aspect of the battery’s operation. It protects the pack from overcharging, over-discharging, and extreme temperatures, and it is responsible for calculating the vehicle’s state of charge and remaining range.

By 2025, the BMS will evolve from a simple monitoring device into an intelligent, AI-powered predictive system.

- Wireless BMS: Traditional BMS systems require a complex, heavy wiring harness to connect to each cell in the pack. Wireless BMS technology, which is expected to enter mass production by 2025, eliminates the need for this wiring. This reduces weight, cost, and complexity, and makes the packs easier to manufacture and service.

- AI and Machine Learning for Predictive Health: The BMS of 2025 will use AI algorithms to create a “digital twin” of the battery. By analyzing the owner’s driving and charging habits, the AI-BMS can predict the battery’s future health with incredible accuracy. It can optimize charging strategies to maximize battery lifespan and provide early warnings of potential cell failures, long before they become a problem.

Keeping It Cool: Advanced Thermal Management Systems

Controlling a battery’s temperature is critical to its performance, longevity, and safety. By 2025, as charging speeds increase and performance demands grow, thermal management systems will become increasingly sophisticated.

The focus is on dissipating heat from the cells as efficiently as possible during fast charging and aggressive driving, while also maintaining their temperature in cold climates.

- Immersion Cooling: For ultra-high-performance EVs, we will begin to see the adoption of immersion cooling. This involves submerging the battery cells directly in a non-conductive, dielectric fluid. This method is significantly more effective at dissipating heat than traditional liquid cooling plates, enabling sustained high-power output and rapid charging without overheating the cells.

- Advanced Heat Pumps: To improve efficiency in cold weather (a major weakness for EVs), advanced heat pump systems will become standard. These systems can scavenge waste heat from the battery, motors, and power electronics and use it to warm the cabin and the battery pack, significantly reducing the impact of cold temperatures on the vehicle’s range.

The Ripple Effect: How Better Batteries Will Transform the Entire EV Ecosystem

The impact of these advanced battery technologies will reverberate far beyond the vehicles themselves. They will act as catalysts, enabling and accelerating a range of changes across the entire electric mobility and energy ecosystem.

The car of 2025 is not just a mode of transport; it is a powerful, grid-connected energy asset.

Supercharging the Infrastructure: The 350+ kW Era

A battery that can charge in 10-15 minutes is useless without a charger that can deliver sufficient power. The advent of 800-volt and even higher voltage battery architectures, combined with advanced thermal management, is pushing charging power well beyond the 150-250 kW common today. By 2025, 350 kW and even faster “Megawatt Charging System” (MCS) chargers for heavy-duty trucks will become the new benchmark, necessitating substantial investments in grid upgrades and new charging station technology.

The Grid on Wheels: Vehicle-to-Grid (V2G) Goes Mainstream

A car is parked 95% of the time. A parked EV with a large battery is a massive, underutilized energy resource. Vehicle-to-Grid (V2G) technology turns every EV into a mobile power plant. The advanced, long-life batteries of 2025, particularly those based on LFP, are perfectly suited for this role.

By 2025, V2G is expected to transition from pilot programs to its first large-scale commercial deployments, facilitated by bidirectional chargers and supportive utility programs.

- Grid Stabilization: During peak demand hours in the evening, a fleet of connected EVs can discharge a small amount of power back to the grid, helping to stabilize it and prevent the need for firing up expensive and polluting “peaker” power plants.

- Home Backup Power (V2H): In the event of a power outage, an EV with V2H (Vehicle-to-Home) capability can power an entire home for several days, providing a clean and silent alternative to a gasoline generator.

- Renewable Energy Integration: V2G is a suitable complement to intermittent renewable energy sources, such as solar and wind. EVs can charge during the day when solar power is abundant and cheap, and then discharge that clean energy back to the grid in the evening.

The Circular Economy: A New Life for Old Batteries

With battery packs designed to last for over a million miles, many will outlive the vehicle in which they are installed. This is creating a massive opportunity for a circular battery economy.

By 2025, the infrastructure for battery second-life and recycling will have matured significantly.

- Second-Life Applications: When an EV battery reaches the end of its automotive life (typically around 70-80% of its original capacity), it is still perfectly suited for less demanding applications. These “second-life” batteries will be repurposed en masse for stationary energy storage systems, providing backup power for homes and businesses and supporting the utility grid at larger scales.

- Advanced Recycling: For batteries that are truly at the end of their life, a new generation of advanced recycling facilities will come online. These will utilize more efficient and environmentally friendly hydrometallurgical processes to recover over 95% of critical materials, including lithium, nickel, cobalt, and manganese, thereby creating a closed-loop supply chain and reducing the need for new mining.

The Grand Challenges: Hurdles on the Road to 2025

The transition to this advanced battery future is not without its monumental challenges. The path to 2025 is a race against time to solve complex technical, logistical, and geopolitical problems.

Successfully navigating these hurdles will be the true test of the industry’s ability to scale this revolution.

The Raw Material Scramble: Securing the Supply Chain

The biggest challenge is securing a reliable, sustainable, and ethical supply of raw materials. The demand for lithium, nickel, cobalt, and even graphite is projected to increase substantially. This is driving a global scramble to secure mining rights and processing capacity.

This geopolitical competition is forcing the industry to diversify its sources and its chemistries.

- Geopolitical Bottlenecks: A huge portion of the world’s battery mineral processing is concentrated in China. This has created a strategic vulnerability that Western countries are now urgently seeking to address by developing their own domestic supply chains.

- The Push for Sustainable Mining: There is intense pressure to ensure that these materials are mined in an environmentally responsible and ethical manner, avoiding the human rights abuses that have plagued cobalt mining in the past.

- The Chemistry Solution: The shift towards LFP and sodium-ion is a direct response to this challenge, as these chemistries rely on more abundant and geographically diverse materials.

Manufacturing at Giga-Scale: From Lab to Production Hell

It is one thing to develop a breakthrough cell in a laboratory. It is an entirely different and immensely difficult challenge to manufacture that cell with perfect quality and consistency at the scale of millions or billions of units per year.

The “gigafactories” of 2025 will be marvels of automation and process control, but getting there is a monumental undertaking.

- Mastering New Processes: New technologies, such as silicon anodes and solid-state electrolytes, require entirely new manufacturing techniques that must be perfected and scaled.

- Quality Control: A single microscopic defect in a battery cell can lead to a catastrophic failure. Maintaining quality control at the gigawatt-hour scale is a huge engineering challenge.

- The Talent Shortage: A global shortage of battery engineers, chemists, and technicians exists, as the skills required to design, build, and operate these massive factories are in high demand.

Conclusion

As we look to 2025, it is clear that the electric vehicle is undergoing its most significant transformation since its modern inception. The battery is evolving from a simple energy-storage device into a highly engineered, intelligent, and structural component that forms the bedrock of the vehicle. The breakthroughs in chemistry—from silicon anodes and LFP to the first solid-state cells—will finally conquer the lingering doubts about range, cost, and longevity. Simultaneously, the revolution in pack architecture, with cell-to-chassis designs and AI-powered management systems, will create a new generation of EVs that are lighter, safer, more spacious, and more efficient to build.

This is more than just an engineering achievement; it is the catalyst for a new energy paradigm. The EV of 2025 is not merely a cleaner car; it is a distributed energy resource and a key player in creating a more resilient and renewable electric grid. The road ahead is fraught with challenges, from securing fragile supply chains to scaling up manufacturing at an unprecedented level. But the trajectory is clear and unstoppable. The technologies that are now maturing and entering the market will, by 2025, reshape not just what we drive, but how we power our lives, marking the moment the electric vehicle revolution truly came of age.