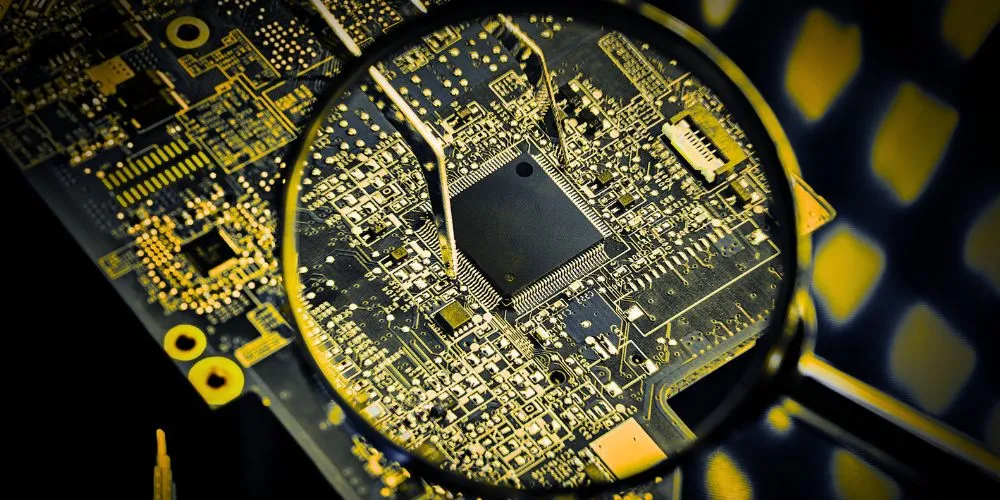

For half a century, the semiconductor chip was the quiet, invisible engine of progress. Etched with billions of microscopic transistors, these slivers of silicon powered our world with a predictable, relentless rhythm, doubling in power every two years in a virtuous cycle known as Moore’s Law. The global supply chain that produced these marvels was a masterpiece of globalization. This hyper-efficient, intricate, and largely invisible web stretched from the design houses of California to the fabrication plants of Taiwan and the assembly lines of Malaysia. Its singular focus was cost optimization, and for decades, it worked flawlessly, delivering ever more powerful chips at ever lower prices, fueling the digital revolution.

That era of quiet, predictable efficiency has been shattered. The chip shortage that began in 2020 was a global wake-up call, a seismic event that sent shockwaves through every sector of the economy. It was the moment the world awoke to a startling reality: the entire modern industrial complex, from automobiles and consumer electronics to critical infrastructure and national defense, is built upon a fragile, geographically concentrated, and geopolitically fraught supply of these tiny, powerful components. The chip is no longer just a component; it has become a strategic asset of immense geopolitical importance. This realization has triggered a profound and lasting reshaping of global supply chains and manufacturing strategies, marking a tectonic shift away from pure cost efficiency and toward a new paradigm defined by resilience, security, and regionalization.

The Perfect Storm: Deconstructing the Great Global Chip Shortage

To understand the radical changes now underway, we must first dissect the anatomy of the crisis that acted as the catalyst. The great chip shortage was not the result of a single event but a “perfect storm”—a confluence of black swan events, structural vulnerabilities, and flawed assumptions that collided to bring the world’s most sophisticated supply chain to its knees.

This crisis was a brutal but necessary stress test that exposed the deep-seated fragilities that had been built into the system over decades of relentless optimization.

The Pandemic Demand Shock: A Miscalculation of Historic Proportions

The initial trigger was the COVID-19 pandemic. As the world went into lockdown, two things happened simultaneously. First, there was a massive, unprecedented surge in demand for electronics. People bought new laptops and webcams to work from home, new gaming consoles for entertainment, and new cloud services to connect it all. Second, automakers, anticipating a deep recession, made a catastrophic miscalculation: they slashed their chip orders, assuming car sales would plummet.

This created a massive and sudden shift in the demand signal being sent to the world’s semiconductor foundries.

- The Foundry Squeeze: Semiconductor fabrication plants (fabs) are incredibly expensive (upwards of $20 billion) and run at near 100% utilization to be profitable. When the automakers cancelled their orders, the foundries didn’t just let their fabs sit idle; they immediately reallocated that production capacity to the booming consumer electronics sector.

- The Bullwhip Effect: When car demand unexpectedly rebounded much faster than anticipated, the automakers found themselves at the back of a very long line. The foundries were already committed to their new customers, and since it can take over a year to bring new fab capacity online, the auto industry was left stranded. This is a classic example of the “bullwhip effect,” where small changes in end-user demand create massive and distorted swings further up the supply chain.

Structural Vulnerabilities Laid Bare

The pandemic was the trigger, but the gun was already loaded. The crisis exposed a series of deep, structural vulnerabilities that had been overlooked for years in the pursuit of efficiency and cost-effectiveness.

These fragilities turned a temporary demand shock into a multi-year global crisis.

- The Folly of “Just-in-Time” (JIT) Manufacturing: For decades, industries such as the automotive sector had perfected the “just-in-time” manufacturing model, where they kept almost no inventory of parts on hand to minimize costs. This worked perfectly in a stable world, but it left them with zero buffer to absorb any supply chain disruption. When the chips stopped coming, the assembly lines ground to a halt almost immediately.

- Extreme Geographic Concentration: The world had allowed the most critical part of the digital economy—leading-edge semiconductor manufacturing—to become dangerously concentrated in one small, geopolitically vulnerable island: Taiwan. Taiwan, and specifically the foundry giant TSMC, accounts for over 90% of the world’s manufacturing of the most advanced logic chips. A single earthquake, drought, or, most terrifyingly, a military conflict in the Taiwan Strait could bring the global tech industry to a standstill.

- The Lack of Supply Chain Transparency: The semiconductor supply chain is notoriously long, complex, and opaque. Most end-user companies, like the automakers, had no direct relationship with the foundries. They bought their chips through a series of intermediaries and Tier-1 suppliers. This meant they had almost no visibility into the upstream supply chain, leaving them unable to anticipate or react to the looming shortages.

- The Neglect of Legacy Nodes: The shortage was not just in the most advanced, cutting-edge chips. A significant portion of the crisis was centered on so-called “legacy” or “mature” nodes—the older, less glamorous chips (e.g., 28nm, 40nm, 90nm) used for essential functions such as power management, display drivers, and microcontrollers. The industry had underinvested in this type of manufacturing capacity for years, creating a critical bottleneck for a huge range of products.

The New Global Playbook: From Efficiency to Resilience and Regionalization

The chip shortage was a traumatic but clarifying event. It has compelled a fundamental reevaluation of supply chain and manufacturing strategies at both the corporate and national levels. The old playbook, which had “cost optimization” as its first, second, and third priorities, has been discarded. The new playbook is being written with a new set of watchwords: resilience, security, and regionalization.

This is not just a temporary adjustment; it is a long-term, structural shift in how the world thinks about and manages the production of its most critical technology.

The Geopolitical Imperative: “Techno-Nationalism” and the Quest for Chip Sovereignty

The most significant driver of this new era is the weaponization of semiconductors in the great power competition between the United States and China. Chips are no longer seen as mere commercial goods; they are viewed as foundational assets for national security and economic competitiveness. This has unleashed a new era of “techno-nationalism” and a global race for “chip sovereignty.”

Governments are now using the full force of industrial policy to onshore and “friend-shore” semiconductor manufacturing.

- The U.S. CHIPS and Science Act: This is the centerpiece of the new American strategy. The CHIPS Act provides over $52 billion in direct subsidies and tax credits to incentivize companies—both domestic and foreign—to build new, advanced semiconductor fabs on U.S. soil. The goal is to reverse a decades-long decline and bring a larger share of the manufacturing back to the country where the chip was invented.

- The European Chips Act: The EU has launched its own multi-billion euro initiative with a similar goal: to double its share of the global semiconductor market to 20% by 2030. It is actively courting companies like Intel and TSMC to build new fabs within the bloc.

- Japan and South Korea’s Defensive Investments: As the incumbent leaders in certain segments of the industry, Japan and South Korea are also investing heavily to protect their positions and bolster their supply chain security.

- China’s Push for Self-Sufficiency: In response to U.S. export controls that have restricted its access to advanced Western technology, China is undertaking a massive, state-directed effort to establish a fully self-sufficient domestic semiconductor industry. This is one of the Chinese government’s highest national priorities.

- The Rise of “Friend-Shoring”: Beyond pure onshoring, governments are promoting a strategy of “friend-shoring”—diversifying supply chains by moving them to allied or geopolitically stable countries. This is leading to new investments in countries like Mexico, India, and Vietnam.

The Corporate Strategy Shift: From “Just-in-Time” to “Just-in-Case”

The corporate world has learned the painful lesson of fragility. The C-suites of major manufacturing companies are now fundamentally reevaluating their supply chain strategies, shifting away from a pure focus on lean efficiency toward a more balanced approach that prioritizes resilience.

This has led to a dramatic reversal of several long-held supply chain dogmas.

- The Return of Inventory (Strategic Buffering): The “zero inventory” ideal of JIT is being replaced by a “just-in-case” strategy that involves building up strategic buffers of critical components. Companies are now willing to bear the cost of holding more inventory as a form of insurance against future disruptions.

- Multi-Sourcing and Supplier Diversification: The practice of relying on a single supplier for a critical component to obtain the best price is now considered unacceptably risky. Companies are actively diversifying their supplier base, even if it means sacrificing some cost efficiency. For chips, this means qualifying multiple foundries or chipmakers for the same part.

- Forging Direct Relationships: The lack of visibility during the shortage has compelled end-user companies, particularly in the automotive industry, to overhaul their chip procurement processes. They are now bypassing their traditional Tier-1 suppliers to forge direct, long-term strategic relationships with the chipmakers and even the foundries themselves. They are co-designing chips, making long-term capacity commitments, and sharing much more detailed demand forecasts.

The Digital Transformation of the Supply Chain: The Quest for Transparency

You cannot manage what you cannot see. The opacity of the semiconductor supply chain was a major contributor to the crisis. In response, there is a significant push to digitally transform the supply chain, utilizing technology to achieve an unprecedented level of end-to-end transparency.

The goal is to create a “digital thread” that can track components from the raw materials to the final product.

- Supply Chain Control Towers: Companies are investing in “control tower” software platforms that ingest data from across their entire supply chain—from suppliers, logistics providers, and their own factories—to provide a single, real-time view of their entire network. This enables them to identify potential disruptions early and respond more quickly.

- AI and Predictive Analytics: Advanced analytics and AI are being used to analyze supply chain data to predict potential bottlenecks. Machine learning models can analyze thousands of variables—from shipping lane congestion and weather patterns to geopolitical risk signals—to provide early warnings of potential disruptions.

- Blockchain for Traceability: Blockchain technology is being explored as a way to create a secure, immutable, and transparent record of a component’s journey through the supply chain. This could be used to verify the provenance of chips and to combat the growing problem of counterfeiting.

The Factory of the Future: How Semiconductor Realities are Reshaping Manufacturing Itself

The shockwaves from the semiconductor industry are not just reconfiguring supply chains; they are also fundamentally reshaping the factory floor. The drive for resilience, combined with the increasing complexity of modern products, is accelerating the adoption of a new generation of smart manufacturing technologies, often referred to as Industry 4.0.

The factory of the future will be more automated, data-driven, and flexible, with the semiconductor chip serving as both the enabler and the driver of this transformation.

The Rise of Automation and Robotics

To bring manufacturing back to high-cost countries in North America and Europe, companies must offset the higher labor costs with a massive increase in automation. At the same time, the manufacturing of complex electronics that utilize advanced semiconductors requires a level of precision that exceeds human capability.

This is leading to a new wave of investment in advanced robotics and automation.

- “Lights-Out” Manufacturing: The ultimate goal for some is “lights-out” manufacturing, a fully automated factory that can run 24/7 with minimal human intervention.

- Collaborative Robots (Cobots): Alongside large industrial robots, a new generation of smaller, more flexible “cobots” is being deployed to work alongside human operators, augmenting their capabilities and taking over repetitive or ergonomically challenging tasks.

The Power of the Digital Twin

A digital twin is a virtual, real-time replica of a physical asset or process. It is one of the most powerful concepts in Industry 4.0. By feeding sensor data from the real-world factory into a sophisticated computer model, manufacturers can create a living, breathing digital version of their entire production line.

This digital replica allows for a new level of optimization, simulation, and predictive maintenance.

- Virtual Commissioning and Optimization: Before a single machine is installed on the factory floor, its digital twin can be used to simulate and optimize the entire production process, identifying bottlenecks and refining workflows in the virtual world, which is far cheaper and faster than doing so in the physical world.

- Predictive Maintenance: By analyzing the real-time data from a machine’s digital twin, AI algorithms can predict when a component is likely to fail before it actually breaks down. This allows maintenance to be scheduled proactively, dramatically reducing unplanned downtime, a significant source of cost and inefficiency.

Additive Manufacturing (3D Printing) for Supply Chain Resilience

Additive manufacturing, also known as 3D printing, is evolving from a tool for rapid prototyping into a viable technology for producing end-use parts and tooling for the factory floor.

3D printing provides a powerful means to enhance supply chain resilience and increase manufacturing flexibility.

- On-Demand Spare Parts: Instead of holding a massive physical inventory of spare parts for factory machinery, a company can maintain a “digital inventory” of 3D design files. When a part breaks, it can be printed on demand, directly on the factory floor, which dramatically reduces downtime and inventory costs.

- Custom Tooling and Jigs: 3D printing is used to rapidly create custom jigs, fixtures, and tools needed to assemble complex electronic products, thereby accelerating the setup of a new production line.

- Re-shoring and Distributed Manufacturing: Additive manufacturing lowers the barrier to entry for manufacturing, potentially enabling a more distributed model where products can be printed closer to the point of consumption, further reducing reliance on long, complex supply chains.

The Importance of a Skilled Workforce

This new, highly automated and data-driven manufacturing paradigm requires a new set of skills. The factory jobs of the future will be less about manual assembly and more about operating, maintaining, and optimizing complex robotic and digital systems. This is creating a massive need to reskill and upskill the manufacturing workforce. The “smart factory” needs “smart technicians”—people with hybrid skills in mechanics, electronics, robotics, and data analytics. This skills transformation is one of the biggest challenges and opportunities in the new era of manufacturing.

Navigating the New Landscape: Strategic Implications for Different Industries

The reshaping of the semiconductor supply chain is not a uniform event. It is creating a different set of challenges and strategic imperatives for different sectors of the economy.

A company’s ability to adapt to this new reality will depend heavily on its position in the value chain and its reliance on specific types of chips.

The Automotive Industry: A Painful but Necessary Transformation

No industry was hit harder by the chip shortage, and no industry is undergoing a more radical transformation in response. The automotive industry has been forced to move from being a passive consumer of chips to an active and strategic participant in the semiconductor ecosystem.

The car of the future is a “data center on wheels,” and automakers are now thinking like tech companies.

- From JIT to Strategic Partnerships: As mentioned, automakers are abandoning pure JIT and are now forming deep, long-term partnerships directly with chipmakers, such as NXP and Infineon, as well as foundries like GlobalFoundries and TSMC. Ford’s strategic collaboration with GlobalFoundries is a landmark example of this new model.

- The Move to Centralized Compute and “Software-Defined Vehicles”: To simplify their incredibly complex and fragmented use of hundreds of individual microcontrollers, automakers are moving toward a centralized compute architecture, utilizing a few very powerful System-on-Chips (SoCs) to control many vehicle functions. This is part of the broader shift to the “software-defined vehicle,” where a car’s features and performance can be updated over-the-air, just like a smartphone. This requires automakers to develop deep in-house expertise in chip design and software development.

- Investing in Silicon Carbide (SiC): The transition to electric vehicles (EVs) is creating a massive demand for a specific type of power semiconductor made from silicon carbide (SiC), which is more efficient for managing high-voltage EV powertrains. Automakers like Tesla and GM are making direct, multi-billion-dollar investments and long-term supply agreements to secure their access to this critical technology.

Consumer Electronics: The Race for the Leading Edge

The consumer electronics industry, led by giants like Apple and Samsung, is the primary driver of demand for the most advanced, leading-edge process nodes. For them, the game is about securing access to the limited capacity at the technological frontier to deliver the performance and power efficiency that their flagship products demand.

Their strategy is focused on deep integration, massive scale, and supply chain control.

- Deep Co-development with Foundries: Apple’s relationship with TSMC is the ultimate example of a deep strategic partnership. Apple is TSMC’s largest and most important customer, and the two companies work in incredibly close collaboration, years in advance, to ensure that TSMC’s next-generation process technology is ready and optimized for Apple’s next-generation iPhone and Mac chips.

- Using Scale to Command Priority: Due to the sheer volume of their orders, companies like Apple can secure priority access to the most advanced manufacturing capacity, effectively outmaneuvering smaller competitors.

- Diversification as a Hedge: While deeply tied to TSMC, these giants are also diversifying. Samsung manufactures its own chips, and there is constant speculation that companies like Apple are encouraging Intel’s new foundry business to create a viable alternative to TSMC in the long term, reducing their single-source dependency.

Cloud Computing and AI: An Insatiable Appetite for Specialized Silicon

The hyperscale cloud providers (Amazon, Microsoft, Google) and the AI industry are now in a class of their own. Their demand for computing power is almost infinite, and they are increasingly designing their own custom chips (such as Google’s TPUs, Amazon’s Graviton, and Trainium chips) to optimize for their specific workloads.

Their strategy focuses on vertical integration and custom silicon to achieve a competitive performance and cost advantage.

- The Vicious Cycle of Custom Silicon: By designing their own chips and having them manufactured by foundries like TSMC, the hyperscalers can create processors that are far more efficient for their specific tasks (like AI training or cloud infrastructure management) than the general-purpose chips they can buy from companies like Intel or AMD. This gives them a powerful performance and cost advantage, which in turn attracts more customers to their cloud platform, fueling the need for even more custom silicon.

- Securing the AI Supply Chain: The current generative AI boom has created an unprecedented shortage of high-end NVIDIA GPUs, which are the workhorses of AI training. This has made securing a supply of these chips the single most important strategic priority for every company in the AI space. It is also a powerful incentive for hyperscalers to accelerate the development of their own custom AI accelerators, thereby reducing their dependence on a single supplier.

Critical Infrastructure and Defense: The National Security Mandate

For the defense, aerospace, and critical infrastructure sectors, the primary concern is not cost, but security, reliability, and guaranteed long-term supply. The chips used in these applications often do not need to be at the leading edge, but they must be incredibly robust and come from a trusted, secure supply chain.

The focus here is on “trusted foundries” and securing the supply of legacy chips.

- Onshoring for National Security: A major goal of the CHIPS Act is to create “trusted foundry” programs in the U.S. that can manufacture chips for sensitive defense and intelligence applications in a secure, onshore environment.

- The Challenge of Legacy Node Security: The defense industry relies heavily on older, mature node chips that have been proven to be reliable over many years. Securing a long-term supply of these chips, which are often no longer a focus for the big foundries, is a major challenge. This is another area where government subsidies are being used to encourage foundries to maintain and invest in this older, but still critical, manufacturing capacity.

The Path Forward: Navigating a More Complex and Uncertain World

The great reshaping of the semiconductor supply chain is still in its early stages of development. The multi-billion-dollar investments in new fabs being made today will take years to come online, and the transition to a more regionalized and resilient model will be a long and complex process.

A new set of trade-offs and increased complexity will shape the future of manufacturing and supply chain management.

The Inevitable Trade-off: Resilience vs. Cost

There is no escaping the fact that a more resilient and regionalized supply chain will be a more expensive one. Duplicating manufacturing capacity in high-cost regions, such as the U.S. and Europe, and holding more inventory will inevitably lead to higher costs. The era of relentless deflation in the cost of electronics may be coming to an end. Companies and consumers will have to adapt to a world where supply chain security comes at a price.

The Ongoing Battle for Talent

Building new fabs is one thing; staffing them is another. The global shortage of semiconductor talent is a massive and growing constraint. The success of the onshoring initiatives in the U.S. and Europe will depend entirely on their ability to build a new generation of skilled engineers and technicians through massive investments in STEM education, university partnerships, and workforce development programs.

The Need for Radical Collaboration

The complexity of the challenges ahead—from securing the supply chain to developing the next generation of manufacturing technology—is too great for any single company or country to solve alone. The future will require a new level of “radical collaboration” between industry rivals, between industry and academia, and between the private sector and government. Initiatives like the public-private R&D consortia envisioned in the CHIPS Act are a model for this new, more collaborative future.

Conclusion

The semiconductor chip has lost its invisibility. The intricate, global dance that brings these tiny marvels into existence is now a subject of boardroom debate and geopolitical strategy. The crisis of the past few years has been a painful but necessary catalyst, forcing a long-overdue reckoning with the fragilities of our hyper-optimized, globalized world.

We are now in the midst of a historic rebalancing, a tectonic shift from a system designed for pure efficiency to one designed for resilience. This is a messy, expensive, and complex process, but it is essential. It is about de-risking the digital bedrock upon which our entire modern civilization is built. The new manufacturing strategies and supply chains that emerge from this period of transformation will be more regionalized, more transparent, more automated, and more complex. Deep, strategic partnerships and constant negotiation between cost and security will define them. The companies and nations that successfully navigate this new landscape will be the ones that understand that in the 21st century, the semiconductor is not just a component; it is destiny.